By Lynn Ascrizzi

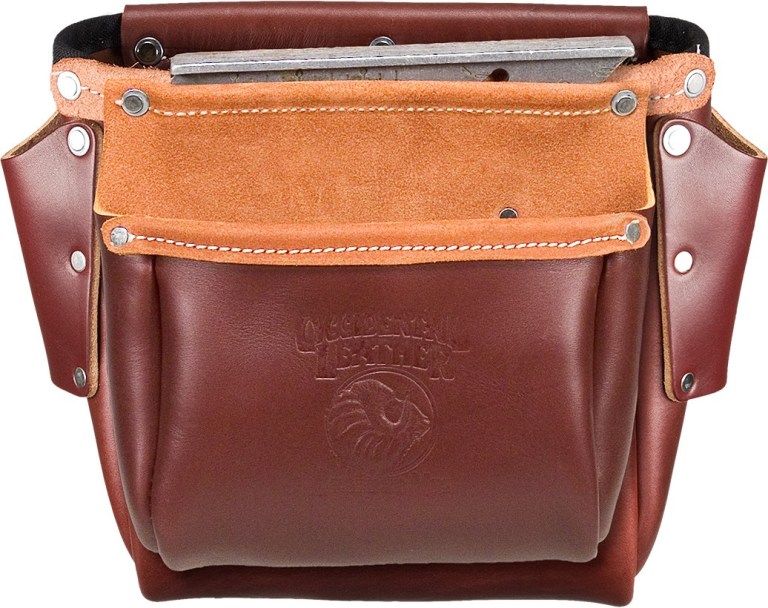

This classic tool belt has been around for 38 years and is the original design of founder Darryl Thurner.

Almost 40 years ago, building contractor Darryl Thurner of Occidental, California, got a little tired of dropping tools on the job. The problem? No quality tool bags were available that fit the special needs of career carpenters.

Being a clever guy, Thurner set out to tackle the problem himself. Based on his own experience, he came up with a rugged design for a “hand-specific,” leather tool bag to carry everyday carpenters’ gear in a well-organized, intuitive way. He took his idea to a California saddle shop and got the leatherworker to make his design. As prototypes evolved, he made some bags for fellow workers.

The tool bags caught on like wildfire, but the saddlemaker did not want to keep on making them. That’s when Thurner taught himself, with local artisans, how to sew leather.

He began to build tool bags by hand in a barn workshop, at his ranch west of Occidental. His work-a-day innovations, which used rugged, high-quality leather, were a nifty blend of old-world craftsmanship and modern technical know-how. He sold his products to local craftsmen and by mail order.

An industrial work of art complemented by a rugged leather luggage handle for carrying comfort, the Occidental Leather Stronghold Journeyman’s Tote is refined functionality at its finest.

Designs quickly evolved. For instance, before 1979, no commercial tool bag had a holder for an angle square. Now, angle squares tucked nicely into a left-side holder and stayed put. Left-side bags also fit nail sets, driver bits, tri-squares and more; right-side holders were designed for handy stuff, like lumber crayons, pencils, levels, tape measures and hammers. Bags were not fixed in place, but could be adjusted on the belt. And, they were customized for “lefties” and “righties.”

Thurner’s ideas nailed it. The start-up business that he and the late Lynn Davis cofounded in 1980, which started as a one-man shop, is today the widely recognized, Occidental Leather Manufacturing, Inc., with offices currently based in Sebastopol, California.

From the get-go, the company set the world standard for top-quality, handcrafted, “function engineered,” tool belt systems and accessories. Its diverse product line is geared to the needs of professional construction workers, builders, framers, dry wallers, ironworkers, commercial electricians and more, with carpenters making up the majority of its end users.

“Occidental Leather is one of the very few manufacturers of tool belt brands exclusively manufactured in the United States,” said company vice-president of operations, Michael Malley, who had joined the company in 1997.

“The superior products our sewers make are very much handcrafted; our competition uses more of a high-production methodology. When it comes to stitchers, we love the old machines. We don’t have any computerized sewing machines. Nobody uses the materials we use. We want the bags to last 20 years,” he said.

THE BIG SURGE

Occidental Leather’s current 15,000-square-foot factory is located in Graton, California. Over the years, the company benefitted from a number of growth spurts, evident in moves to different locations and larger, attractively-designed facilities. But now, the winds of fortune promise to bring even bigger expansion opportunities and a new and spacious workspace.

Last September, Occidental Leather was acquired by U.S. Tape of Pennsburg, Pennsylvania. The company, founded in 1876, produces professional-grade tape measures and other marking and measuring tools for masonry and construction industries.

The transition, Malley admitted, caused him and other employees more than a bit of new ownership angst. But, when the sale went through and U.S. Tape president Peter Rosenquist came on board to also head up Occidental, the experience turned out to be refreshingly positive.

“He is energetic and easy to work with,” Malley said, with enthusiasm and a tinge of relief. “He acquired the business, mainly because he came out here and saw what we’re doing and how we’re doing it. He told us, ‘You guys know what you’re doing.’ ”

He reflected on what was behind Rosenquist’s selection: “We are making a high-quality product. We are all very passionate about what we do. I believe he looked at that and recognized that. That was a main driving force in his decision making. He saw we were doing a great business.”

Another plus, Occidental survived the 2008 Great Recession that hammered the construction industry. “Around 2010, things really took off,” he said, of the surge in sales that soon followed the downturn. “People voted with their dollars. People were investing in themselves and in the U.S.”

He pointed out, however, that the sale was difficult for founder Thurner. “But, he recognized that it was time to reap the rewards of his life’s work,” Malley said. “Darryl was selective about who he sold the business to. There were a lot of ‘suitors’ looking at Occidental — big, international companies. He sold to U.S. Tape because of a promise that Peter made to him: To not take the business overseas, but to carry the quality and characteristics it is known for, today, into the future — profit, quality, customer service. There’s a lot of moving parts that made Occidental work,” he said.

The two companies share a certain commonality. Like Occidental Leather, U.S. Tape caters to professionals instead of do-it-yourselfers attracted to big box retail stores. And, U.S. Tape produces and distributes handy construction-industry items, like tape measures, marking chalk and folding rulers, tools often put into a carpenter’s tool bag.

“We were busting at the seams,” Malley noted, referring to the busy Graton facility. “We needed a little more resources. Peter is allowing us to do that, by providing that financial resource. We’re going to experience an expansion mode. We’ve hired 20 percent more production workers. New personnel are on board. We are getting positive direction from our new owners.”

A boost in working capital materialized this year in the form of a recently leased, 29,000-square-foot facility in Santa Rosa, California. When the move is completed this fall, it will represent a 50 percent expansion. This means more room for the company’s 58 full-time employees — which include seven office workers and the 51 skilled production workers who make each product, from start to finish. The move, which keeps the location in Sonoma County, also will provide more space for inventory and projected growth.

“It’s going to be a good move,” Malley said.

Peter Rosenquist, new President of Occidental Leather with long-time employee and VP of Operations Michael Malley.

Company sales manager, Susan Alberts, shared her insights. “It was a small, family-owned company for 38 years. Most employees have been here for 20 years. We’re one of the rarities. We have a lot of valued dealers, large and small. We do not sell to end-users. We sell directly to our dealer network.”

“We’re targeting customers who deal strictly with people in construction — someone in the trades,” Malley explained.

“Occidental sells through a network of dealers online and at a retail level,” Alberts added. “Our tool belts, bags and other products are sold only through quality building suppliers and hardware retailers — places like small lumber yards and hardware stores, up to mega-construction suppliers, like SouthernCarlson and HD Supply White Cap — places where construction guys go to buy materials, supplies and products.“

CONSISTENT QUALITY

Occidental offers about 180 individual products, which include work-specific, tool bag designs made of all leather, nylon and leather, and nylon. The company also makes leather and nylon suspension (suspender) systems, belt-free and vest systems, and more. They also manufacture a number of accessories, like tool work belts, cell phone holders and clip-on gear pockets.

“Our Cadillac of bag sets is the #5191 Pro Carpenter’s Five-Bag Assembly, based on the original design that Darryl made,” Malley said. “Its list price today is about $380. Our most reasonable product is the #8385 Black Belt Rough Framer, a 3-bag nylon set that lists for just under $220.”

Sixty percent of tool bags sold are made of heavy-duty, top-grain cowhide. Nylon-and-leather combo bags make up 30 percent of sales. The remaining sales are from nylon bags.

All materials used, except hardware, are selected from U.S. companies. Bag leather is purchased from a Milwaukee tannery. Matt Foster, owner of Maverick Leather of Bend, Oregon, is Occidental’s sales rep for the tannery. Nylon is sourced from a fabric dealer in Southern California, a product made in an East Coast mill.

When it comes to leather, quality and consistency are crucial. “We have specific tannage for chrome-tanned leather that the tannery makes for us. It holds up for exterior use and is very durable,” Malley said. For belt leather, the company uses a tannery in Pennsylvania.

“For our (tool) belts, we get a thicker, veg-tan leather, which is a bit stiffer. It’s specifically tanned to our requirements — not too soft, not too firm — the goldilocks effect — just right,” he explained. “We ask our tanners that the leather does not have a flat, cadaver look. We make our bags with an aniline look to the leather. You can see the grain and all its characteristics. The coloration is on the grain side. It looks professional to the eye as well as functional. We have a grasp on the aesthetics of the product.”

The company’s most popular nylon bags are those that have leather tool holders. “Leather holds up better. Nylon is more expensive for us to make. Nylon takes more time. We lower the price on nylon bags because of the public perception. People in the Northwest lean toward nylon bags. They get a lot of rain out there. We need to bind all the raw edges of the nylon, to prevent fraying of the fabric itself. We don’t need to do that on the leather. We sell more leather bags than nylon,” he said.

Interestingly, nylon belt systems are about one pound lighter than leather ones. What matters, Malley pointed out, is how much gear gets put in a tool pouch, like hundreds of nails. “It’s what you’re carrying around your waist. It’s a brutal thing to load your tool bag up with 30 pounds and keep it there all day. It’s one of the reasons we came up with the suspension system. It takes the weight off your hips and puts it on your shoulders.”

Iron Workers Leather Bolt Bag

Occidental’s quality tool bag systems are the envy of the world. But, some of the attention the company gets from the global marketplace is not in the company’s best interest.

“China and India have been knocking off our products, left and right,” he said. But, in his opinion, the knock-offs “offer no quality, or they have inferior quality and craftsmanship — cheap leather and cheap hardware.”

How do they hold the line?

“We just keep on doing what we do. The fact is, carpenters are intelligent and well-thought-out folks. After a couple of go-rounds with inferior tool bag sets, they realize they could have an Occidental bag around their waist that lasts into the future. They realize the good economics in spending more,” he said.

Designed exclusively for journeyman electricians, the electrician’s tool case has 25 pockets to accommodate all tools of the trade.

ICONIC STATUS, PRIDE & SATISFACTION

Great pride is taken in the skilled work accomplished in the factory. If given proper notification, folks like Malley and Alberts often give personal tours.

“We’re more than happy to show people around. A tour of the factory is worth it,” Malley said. “You have to see what our sewers and cutters do — to see them work and use their hands — how they work the leather. It’s amazing! People really appreciate it, when they see how things are made, first-hand.”

(For an online tour and product demonstrations, those interested can click on the cool videos posted at the company’s website: occidentalleather.com.)

Customers also can send in their worn tool bags for repairs. “I’ll ask people, what’s wrong with your old set? Send it in to us. We’ll restitch the holes and do all the labor, free,” he said. “If a customer has a rivet missing or something is wrong with a bag, call us at Occidental. If it’s our mistake, we’re on it. We’ll take care of you.”

He shared a recent anecdote. “Last week, we were sent two (tool bag) sets, handed down from father to son. They were from the ’80s. It’s amazing. They’re like heritage pieces.”

Even though the manufacturer does not sell directly to the public, Malley’s passion for serving the customer finds him spending time on the phone talking to end users. “We only sell to dealers, because they’re supposed to take care of the buyer. But dealers cannot always point a user in the right direction. So, customers call Occidental,” he said.

Sticking to high quality and its made-in-USA position has given Occidental Leather an iconic status. “We stay up at night and look at Facebook postings and Instagram. We have almost a cult following, like Harley Davidson. A vast number of carpenters wear Occidental bags. We hear that a lot.

“We’re standing on the shoulders of giants who created this company. It grew larger than we anticipated. If you treat people the right way, it pays off,” he said.

ONE TOUGH OX

Occidental Leather Manufacturing, Inc., currently based in Sebastopol, California, has for its trademark, a carved depiction of a musk ox, an animal that battles some of the harshest winters on the planet. It was chosen as a symbol, according to company vice-president Michael Malley, because “OX” sounds like the first syllable in “OX-i-dental.”

It is obvious that the symbol also suggests the rugged tool bag systems that Occidental Leather manufactures, which are tough, strong and durable. Moreover, musk oxen tackle problems head on. They’re team players, outsmarting the wolf pack by forming a protective circle.

CONTACTS

Occidental Manufacturing, Inc.

4200 Ross Road

Sebastopol CA 95472

(707) 824-2560

Fax (707) 824-2570

Michael Malley, vice-president of operations: mm@occidentalleather.com

Susan Alberts, sales manager: susan@occidentalleather.com

Courtesy of: The Leather Retailers’ and Manufacturers’ Journal